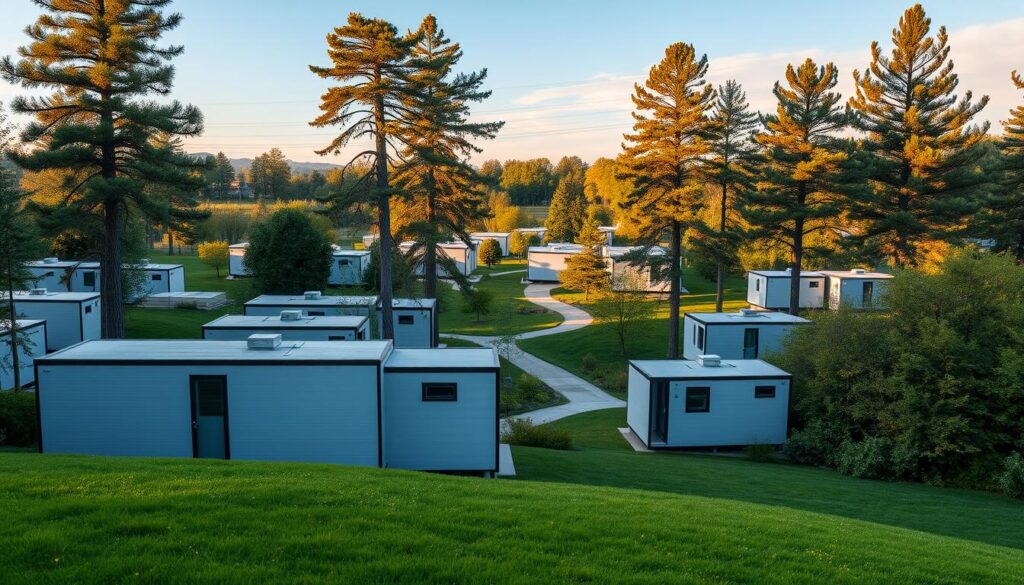

Modular homes are reshaping how we think about compact living. Factory-built modules arrive on site and join together in weeks, cutting build time and site disruption. Controlled production lowers waste and boosts quality.

Data shows real gains: a U.K. factory sent zero waste to landfill for years, and modular projects can cut vehicle trips by up to 80%. Research also found up to 45% less embodied carbon compared with traditional methods.

This approach brings clear advantages for households: faster delivery, predictable quality, smarter energy use, and better use of limited space. Yet risks exist too. Some big firms left the market due to capital strain and macro headwinds.

In this guide, we map how modular housing fits into U.S. housing choices and why factory-built building can be a durable, scalable solution. Expect data, honest trade-offs, and practical insights for modern living.

Key Takeaways

- Factory-built modules speed construction from months to weeks.

- Modular methods reduce waste and lower embodied carbon.

- Benefits include less neighborhood disruption and better energy performance.

- Capital intensity created market exits, so challenges remain.

- Modular units suit compact space and modern living needs.

What Portable and Modular Homes Really Are—and Why They Matter in a Tight Housing Market

Standardized units made in controlled plants shrink schedules and reduce surprises.

Defining terms and key differences

Modular construction uses factory-built volumetric units that join on site. That contrasts with traditional construction that assembles most pieces at the lot. A modular home may arrive with kitchen and bath finished, so on-site time drops dramatically.

Why factory-built methods emerged

Roots run deep, from early 1900s mail-order kits to modern tech-enabled plants. Builders turned to offsite production to cut delays, lower waste, and meet urgent housing needs.

- Speed: faster delivery and earlier occupancy.

- Predictability: lower cost variance and less rework.

- Sustainability: reduced waste and better energy performance than many site-built options.

Across the world, higher offsite shares in places like Sweden and Japan show what scale can deliver. For U.S. markets facing tight supply, modular homes offer a clear advantage.

Inside the Factory: Innovations Powering Faster, Greener, Higher-Quality Homes

Modern assembly lines cut on-site time by weeks, turning complex building schedules into predictable runs. Entire modules are produced in factories and joined on site in a matter of weeks, not months. This speed helps developers meet urgent demand and lower schedule risk.

Speed and consistent quality

Standardized construction methods let teams repeat tasks with precision. Precision tools and robust QA reduce defects that often come from weather and site variability.

Energy, waste, and logistics gains

Factory settings enable better insulation, tighter envelopes, and smarter energy systems. Studies show up to 45% less embodied carbon and major waste cuts. Some factories reached zero waste to landfill while projects cut truck trips by as much as 80%.

Customization, compact living, and rapid deployment

Manufacturers offer strong customization and flexibility, so modules fit unique layouts and lifestyles. Designs focus on multi-use rooms, smart storage, and compact efficiency.

- Cleaner sites: fewer vehicle movements and shorter on-site windows mean less neighborhood disruption.

- Repeatable quality: indoor workflows maintain consistent tolerances across projects.

- Quick shelter: rapid-deployment projects show how these methods scale in emergencies.

Global Snapshot and U.S. Outlook: Where Modular Leads Today and Where It’s Headed Tomorrow

Several countries have scaled offsite manufacturing into mainstream building at impressive rates. This section compares leaders, current U.S. share, and market momentum.

Leaders in action

Sweden uses offsite methods for about 45% of new units. That shift helps crews beat short outdoor seasons and cut waste.

Japan applies modern methods to roughly 15–20% of new starts, or about 150,000–180,000 annually. These programs show how scale brings speed and consistent quality.

The U.S. baseline and growth room

Today, less than 4% of U.S. stock was built with modular techniques. That low share signals large room to grow for modular construction in housing and multifamily building.

Market momentum and drivers

Global modular construction is valued near $82.3 billion and may reach $139.03 billion by 2029 at a 6.2% CAGR. Urbanization, sustainability targets, and demand for faster delivery drive adoption.

- Lesson: adapt proven methods to local codes, financing, and supply chains.

- Result: more pilots where time savings and cost control align with developer goals.

Barriers to Scale—and Practical Paths Forward

Scaling modular models faces real limits, but clear steps can reduce risk and speed results.

Logistics and site constraints

Transport rules set strict size limits that complicate deliveries past trees and power lines. Wide loads need escorts and careful routing.

Urban projects struggle to find staging space near a lot. Teams must plan crane lifts, materials handling, and just-in-time deliveries to avoid delays and reduce waste.

Capital, cycles, and market pressure

High upfront cost to start built factories exposes firms to pipeline volatility. Recent exits like Katerra and some U.K. firms show how capital and market swings matter.

“Many failures trace to thin pipelines and sudden macro shifts that leave factories underused.”

Hybrid and panelized options

Practical paths: combine modules for repeatable rooms and panelized or on-site framing for large-span spaces.

- Use modular elements where they add speed and quality.

- Finish big open areas on site to keep design flexibility and lower transport friction.

- Leverage public-private partnerships and standardized specs to smooth demand and de-risk factories.

Outcome: Owners and builders can pick a balanced option that fits budget, schedule, and community needs while improving quality and lowering waste and environmental impact.

Charting the Road Ahead for the Future of Portable Homes in the United States

Experts expect broader adoption in the U.S. Hybrid production and panelized methods will help meet urgent housing needs while keeping construction schedules tight.

Policy action and pooled demand can speed scaled projects, align financing, and reward energy performance and low-carbon materials. That means more measurable sustainability and clearer value over time.

For buyers, modular home options bring real customization and flexibility. Owners gain speed, reliable quality, and space-smart design that fits budgets and lifestyles.

As supply chains mature, skilled factory jobs will rise and on-site assembly will become smoother. With strong data on energy, quality, and schedule, this industry can win broader trust and deliver better housing outcomes faster.

Leave a Reply