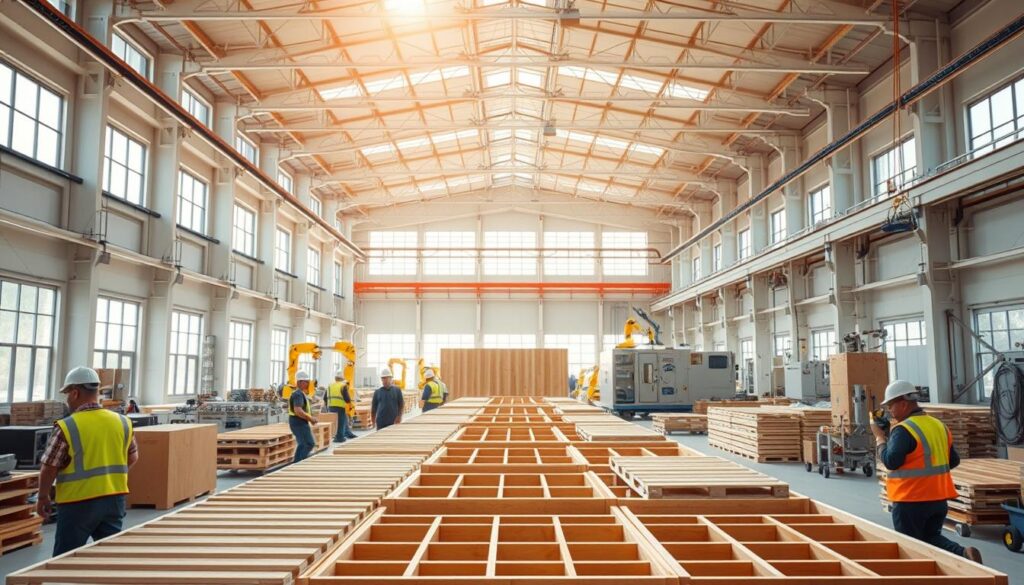

Prefabricated and modular houses bring a new level of practicality to sustainable living. Built off-site in controlled factories, these units cut construction waste, limit site disruption, and deliver consistent quality. Factory precision helps create tight building envelopes, efficient windows, and better insulation for lower energy use.

Modern designs pair stylish finishes with high-performance systems. Many builders use responsibly sourced wood and other conscious materials. These homes are adaptable — from compact ADUs to larger family layouts — and they arrive ready for smart controls or renewable integration.

The real benefits show up in bills and comfort. Owners can expect lower utility costs, improved indoor air, and a faster path to occupancy versus traditional construction. The article that follows breaks down benefits, certifications, pricing, materials, and timelines to help you move from idea to action with confidence.

Key Takeaways

- Factory-built quality reduces waste and improves energy performance.

- Designs scale from small ADUs to full family layouts with minimal disruption.

- High-quality materials and tight envelopes cut utility costs and boost comfort.

- Prefab options are ready for smart energy and net-zero upgrades.

- Faster construction preserves the site and speeds move-in timelines.

Why Portable, Prefab, and Modular Homes Are Reshaping Sustainable Living

Factory-built modules are changing how Americans think about housing by cutting timelines and environmental costs. Demand for modular homes is rising because they combine faster construction with lower environmental impact and tighter quality control than a traditional home.

Factory precision limits on-site disturbance and cuts waste. Builders reduce trips to the site, which lowers carbon and transportation emissions. The result is a more predictable build schedule and less weather-related delay.

Many modular designs emphasize energy efficiency with better insulation, tighter envelopes, and efficient glazing. These features improve thermal comfort year-round and translate into reduced utility bills for homeowners.

Materials matter. Several manufacturers use sustainably harvested wood and low-VOC finishes to support healthier indoor air. Some models are affordable — including options under $100K — widening access for first-time buyers and downsizers.

“Off-site building is enabling green building practices at scale while keeping costs competitive and quality consistent.”

Sections ahead will unpack certification paths, pricing frameworks, and practical steps to plan and purchase a prefab or modular home so you can compare options and set realistic expectations.

- Lower waste: precision cutting and less material loss.

- Reduced carbon: fewer site trips and consolidated logistics.

- Better performance: insulation and air sealing that cut energy use.

Eco-Friendly Portable Homes: Sustainable Living Made Simple

C. When major portions of a house are assembled in a factory, waste falls and schedules tighten while quality rises.

- Lower energy bills: tight envelopes, efficient systems, and careful material selection cut ongoing costs.

- Faster timelines: parallel site prep and factory construction compress the move-in schedule.

- Cleaner indoor air: low-VOC finishes and controlled assembly reduce contaminants and moisture risk.

- Durability: precise construction and high-quality materials help the house withstand climate swings.

- Affordability and choice: options range from budget-conscious models to high-performance designs.

Who this option suits best in the United States

Good fits include first-time buyers, downsizers, remote workers needing a dedicated living space, and families wanting flexible layouts.

Modular homes allow adaptable design and future expansion without major disruption. Strong factory quality control limits rework and waste, improving cost and schedule reliability.

“Factory precision helps homeowners get predictable performance and fewer surprises.”

Next up: we’ll dive into certifications, price snapshots, and material choices that affect performance and resale.

List of Core Benefits You’ll Notice from Day One

You’ll notice lower utility bills almost immediately thanks to tighter building envelopes and efficient systems. Prefab designs combine better insulation, efficient windows, and right-sized HVAC to reduce loads. That translates into visible savings in the first month and compounding cost savings over years.

Immediate energy savings and long-term cost reductions

Tighter envelopes and efficient glazing cut drafts and lower heating and cooling runs. Right-sized systems avoid wasteful cycling and extend equipment life. Over time, these gains add to lower maintenance and reduced lifetime cost.

Cleaner indoor air with low-VOC finishes

Low-VOC paints and finishes improve air quality from day one. Families with allergies or sensitivities notice fewer odors and fewer airborne irritants. This boosts daily comfort and can reduce visits related to respiratory issues.

Smaller environmental footprint with right-sized space

Optimized layouts use fewer materials and reduce lifecycle impact without compromising comfort. Factory construction ensures consistent quality across builds, so the house performs as designed in different climates.

| Benefit | Immediate Effect | Long-Term Impact |

|---|---|---|

| Improved envelope | Lower monthly bills | Reduced energy use, higher resale value |

| Low-VOC materials | Cleaner indoor air | Fewer health-related costs |

| Right-sized space & systems | Efficient operation | Less maintenance, lower lifecycle cost |

Tip: Prioritize features that deliver the biggest returns first—insulation, windows, and a tight envelope—then add smart controls to monitor usage and boost savings. This option supports adaptable layouts so your living needs can change without wasteful renovations.

Green Building Certifications That Add Real Value

Third-party credentials help buyers, lenders, and appraisers trust that a project will perform as promised. Certifications convert technical choices into verified results that often unlock incentives and boost resale confidence.

LEED: holistic sustainability scoring

LEED assesses energy, water, materials, site, and indoor air to produce a balanced scorecard for a home. This framework rewards thoughtful material selection and site design while tracking overall sustainability.

ENERGY STAR: proven energy performance

ENERGY STAR verifies measured energy results. A certified home typically shows lower bills and more consistent comfort thanks to tested systems and inspections.

Passive House & Living Building Challenge: peak efficiency standards

Passive House relies on airtightness, superior insulation, and thermal-bridge control to slash heating and cooling demand. The Living Building Challenge goes further, demanding deep cuts in energy, water, and material impacts across construction and occupancy.

How to pick a path: match your climate, budget, and goals. Ask builders for past certified projects and measured performance data before you commit.

| Program | Focus | Key benefit |

|---|---|---|

| LEED | Energy, water, materials, IAQ | Balanced sustainability score |

| ENERGY STAR | Verified energy performance | Lower utility bills & comfort |

| Passive House | Thermal efficiency standards | Minimal heating/cooling need |

| Living Building Challenge | Whole-system rigor | Deep reductions in resource use |

Cost and Price Snapshot: From Budget Builds to High-Performance Homes

A clear price snapshot reveals how factory practices and material choices shape final costs. This helps buyers compare offers and focus on value, not just the sticker price.

Understanding per-square-foot pricing and what’s included

Typical modular pricing averages about $100–$200 per square foot. That usually covers the shell, basic finishes, and standard systems.

Land, site prep, utility hookups, foundation work, and major customizations are often excluded and add to the final price.

Typical ranges for a 2,000 sq ft modular home

A 2,000 sq ft home commonly ranges from roughly $200,000 to $400,000 before land and site expenses. Optional upgrades—solar readiness, premium finishes, or certification paths—raise the total.

Where cost savings come from in the factory construction process

Factory repetition, bulk purchasing of materials, and precision cutting lower unit costs. Parallel site prep and module build compress time and reduce weather delays and related risk.

Studies show 10%–30% lower per-square-foot costs versus conventional construction, which translates into meaningful savings for homeowners.

| Item | Typical Inclusion | Impact on price | Notes |

|---|---|---|---|

| Base build | Structure, basic finishes, HVAC | Majority of per-sq-ft price | Customs may add 10%–30% |

| Site & foundation | Excavation, foundation, hookups | Separately billed | Varies by lot and soil |

| Upgrades | Solar prep, premium materials | Increases total cost | Boosts energy efficiency and value |

| Factory efficiencies | Bulk buying, less waste | Reduces costs 10%–30% | Shorter time to occupancy |

Tip: Ask for an itemized scope from builders. That makes it easier to compare price, spot exclusions, and align your budget with envelope and energy efficiency upgrades that give the best long-term value.

Inside the Construction Process: How Factory Builds Produce Less Waste

A controlled shop floor turns repeatable steps into measurable reductions in scrap and rework. The factory construction process brings tasks into a stable environment so teams can follow tight standards for every module.

Controlled environments and precision cutting

Precision cutting and inventory control cut material waste by about 30% versus many site-built projects. CNC tools and jigs reduce offcuts and ensure consistent parts for the homes built in each run.

Fewer site trips, lower carbon impact

Bundled deliveries mean fewer truck trips to the site. That reduces carbon emissions and eases neighborhood disruption during the on-site phase.

- Reduced variability: consistent build steps deliver homes that meet the same tolerances every time.

- Protected materials: covered storage and sequencing prevent weather damage and schedule delays.

- Less rework: tighter tolerances and quality checks lower labor and material risk.

- Better performance: improved alignment and airtightness translate to higher durability and occupant comfort.

“Moving key assembly steps indoors lowers waste, shortens schedules, and improves long-term building performance.”

Bottom line: the factory approach helps produce less waste, cut carbon, and deliver homes that perform better over time while keeping sites cleaner and quieter during installation.

Energy Efficiency Features that Drive Performance

A small set of targeted upgrades often changes how a house performs. Start with the envelope: sealing gaps and adding high-performance insulation gives the biggest energy wins.

High-performance insulation and air sealing

Insulation levels and airtight construction cut drafts and stabilize indoor temperatures. A well-sealed shell reduces the runtime on heating and cooling equipment and lowers bills.

Efficient windows, HVAC, and ENERGY STAR appliances

Efficient windows and tight doors limit heat transfer and boost comfort. Right-sized HVAC systems work more efficiently when loads are predictable.

ENERGY STAR appliances reduce background energy use so the house uses less power without sacrificing convenience.

Solar-ready designs and net-zero options

Many modular designs include roof layouts and pre-wiring for PV. That streamlines future solar installs and makes a net-zero retrofit more affordable.

Smart controls and measured performance matter. Automated thermostats and lighting schedules trim wasted runtime. Tighter envelopes cut noise and stabilize temperatures, which owners notice immediately.

| Feature | Benefit | Why it matters |

|---|---|---|

| High R-value insulation | Lower heat loss/gain | Reduces HVAC runtime and bills |

| Airtight construction | Fewer drafts | Improves comfort and measured performance |

| Efficient windows/doors | Less thermal bridging | Better comfort and reduced energy use |

| Right-sized HVAC & ENERGY STAR | Efficient conditioning | Longer equipment life, lower loads |

| Solar-ready roof & wiring | Simpler PV add-on | Path to net-zero with lower upfront disruption |

Maintenance is straightforward: clean filters, seal ducts, and schedule periodic checks to keep efficiency high. Prioritize the envelope and mechanical systems first for the best return on investment.

Sustainable Materials and Smart Design Choices

Choosing the right building materials shapes both performance and the long-term cost of a home.

Recycled steel and responsibly harvested wood lower carbon and keep strength high. Builders use these materials to cut embodied impact without sacrificing structure.

Bamboo is fast-renewing and durable. As a finish material it offers warmth and a low lifecycle footprint compared with slower-growing hardwoods.

Durability reduces lifetime costs. Longer-lasting assemblies mean fewer replacements and less disruption for homeowners.

- Standardized dimensions and panelization produce less offcut material and help produce less waste on site.

- Tighter assemblies, quality insulation, and moisture management keep performance stable over time.

- Low-VOC finishes and certified products improve indoor air quality and lower overall impact.

Ask for Environmental Product Declarations (EPDs) and chain-of-custody documents for key products. Thoughtful design aligns structure, finishes, and systems so homes are easier to maintain and upgrade.

Build for longevity: a resilient, well-specified home reduces costs, boosts resale, and supports greener living.

Timeline Advantages: Faster Builds, Fewer Weather Delays

Factory schedules and site prep run side-by-side to shave weeks off the total build time. This approach compresses the calendar so you move into your home much sooner than with traditional on-site work.

Because much of the work happens indoors, crews avoid common weather interruptions. That makes the schedule more predictable and reduces costly pauses during construction.

Fewer site visits and bundled deliveries also cut neighborhood disruption. Reduced truck trips lower carbon output and help keep the site tidy with less waste.

Modules arrive ready for fast assembly. That means quick craning, compact staging, and minimal impact to the usable space on your lot.

- Parallel factory assembly and site work shorten overall time.

- Standardized workflows reduce rework and improve quality control in building.

- Predictable milestones lower financing carry and scheduling uncertainty for the house.

“Faster, cleaner builds create a better experience for owners and neighbors alike.”

Plan inspections and utility hookups to match module delivery. That coordination smooths the process and helps your new house open on schedule.

Design Flexibility: Modular Options, Adaptable Layouts, and Space Efficiency

Good design starts with a plan that lets a home change as needs do. Modular systems enable open-plan cores that promote natural light and easy circulation while still giving private zones where needed.

Open plans, ADU add-ons, and future expansions

Prefabricated grids and stacking strategies make adding an ADU or extra room straightforward. Builders often include ready connections so a new living space links to existing mechanicals with minimal construction disruption.

- Open plans: optimize flow and daylight while preserving privacy with partial walls or movable partitions.

- ADU-ready options: stacking and knock-out panels speed later additions and protect original finishes.

- Space efficiency: built-ins, pocket doors, and multiuse rooms reduce square footage but keep full function.

- Aging-in-place features: wider halls, zero-step entries, and simple layout swaps extend a house’s usefulness for decades.

- Less waste: modular construction and smart planning lower material use and speed installs, cutting overall waste.

Design-first thinking that aligns daylighting, ventilation, and storage expands perceived space and avoids costly add-ons. Flexible layouts let families evolve without major remodels, keeping the home fit for changing work, hobby, and family patterns.

Compact Solutions: Tiny Homes, ADUs, and Backyard Studios

Tiny-footprint units pack practical features that make big differences in daily costs and comfort. ADUs and small studios assemble quickly and cause minimal site disruption, so you get usable space fast.

When a small footprint delivers big benefits

These compact builds lower operating costs, speed installation, and offer flexible use. They work as a quiet office, a guest suite, a rental, or a creative studio, giving homeowners multiple options.

Use cases: home office, guest suite, or rental

Modular homes and prefab ADUs simplify additions compared with on-site builds. Factory documentation often eases permitting and shortens timelines for housing add-ons.

Space-smart design—built-ins, convertible furniture, and clever storage—makes a small living space feel generous. These units disturb yards less, suit tight urban lots, and can support multi-generational privacy in the same house.

“Right-sized choices reduce embodied impacts and lower long-term maintenance.”

Tip: Match finishes to the main home, consider solar-ready roofs, and pick the option that best fits site rules and long-term use.

Top Affordable Eco-Friendly Modular Options to Explore

Budget-focused modular lines now pair tight envelopes with tested controls to cut monthly bills. Many of these series hit price points that are roughly 10%–30% lower per square foot while keeping core performance features intact.

Energy-efficient series prioritize insulation, efficient windows, and ENERGY STAR appliances so homeowners see immediate savings. These packages often include right-sized HVAC and pre-wiring for smart thermostats.

Smart-home ready models come with integrated lighting, security, and HVAC controls. That integration simplifies daily operation and can improve efficiency without costly retrofits.

Models targeting third-party standards

Some manufacturers pursue LEED, Passive House, or net-zero goals. Green building certifications and measured test reports help verify long-term performance to buyers and lenders.

| Option | Typical focus | Trade-off |

|---|---|---|

| Base cost series | Essential efficiency features | Lower price, fewer upgrades |

| Smart-ready line | Controls & connectivity | Moderate cost, easy add-ons |

| Certified models | LEED/Passive House | Higher upfront costs, verified savings |

Materials matter: recycled content and responsibly sourced wood lower embodied impact and help balance durability with costs. Thoughtful design reduces lifetime maintenance and boosts perceived quality.

- Compare builders’ test data and building certifications before buying.

- Weigh baseline price against upgrade paths for solar readiness and better windows.

- Bundle efficiency and comfort upgrades for the best long-term value.

“Pick options that deliver real performance in your climate, not just glossy features.”

How to Choose the Right Portable Home for Your Climate and Lifestyle

Climate-aware choices — from insulation levels to window U-factors — make the biggest difference in comfort and monthly bills. Start by listing local challenges: cold winters, hot summers, humidity, or wildfire risk. That list guides material and design trade-offs.

Matching insulation and windows to local weather

In cold regions, prioritize higher R-values and airtight details to reduce heating runs. In hot climates, focus on solar shading, lower SHGC windows, and cross ventilation to cut cooling loads.

Choose windows with U-factor and SHGC ratings that suit your climate. Pair them with proper insulation for the best return on energy upgrades.

Prioritizing features vs. budget

Envelope and HVAC upgrades typically deliver the largest efficiency gains. Spend on insulation, quality windows, and a right-sized HVAC before splurging on finishes.

- Design to boost daylighting and natural ventilation to reduce mechanical use.

- Plan for snow loads, humidity control, or ember-resistant assemblies by region.

- Use modular homes options to orient the house for passive gains and future expansion.

| Priority | What to Select | Reason |

|---|---|---|

| Envelope | High R-value, airtightness | Biggest cut in energy use |

| Windows | Correct U-factor & SHGC | Match solar gain to climate |

| HVAC | Right-sized, efficient unit | Improves comfort and lowers bills |

| Finishes | Durable, low-VOC options | Better indoor air and less maintenance |

Create a phased upgrade roadmap so you can add features over time without rework. Verify performance with blower door testing and measured reports when possible.

“Performance verification saves money and surprises later.”

Financing Paths in the United States: From FHA to Traditional Mortgages

Securing credit for a factory-built house requires clear documentation of standards and a lender who understands the process. Early planning helps the loan review go smoothly and keeps the expected costs and price clear for everyone involved.

Loan types commonly used for modular and prefab homes

- FHA loans — available when the unit is set on a permanent foundation and meets HUD rules.

- Conventional mortgages — often used when appraisals show comparable sales and standard certifications.

- Construction-to-permanent loans — combine interim draws with a single close for final mortgage funding.

What lenders look for: certifications, appraisals, and site prep

Appraisers treat the unit like any other house by comparing recent sales and confirming a permanent foundation. Lenders want documented standards, clear scope, and a realistic construction process that limits risk.

| Item | Why it matters | Typical evidence |

|---|---|---|

| Appraisal | Sets valuation for the mortgage | Comparables, foundation photos |

| Certifications | Reduces underwriting uncertainty | Third-party reports, ENERGY STAR, or test data |

| Site prep plan | Controls schedule and draw timing | Permit copies, contractor scope, contingency budget |

Tip: Work with an experienced builder and local lender early. Verified specs, efficiency documentation, and warranty terms improve underwriting outcomes and help homeowners secure better rates.

“Strong paperwork shortens reviews and can improve loan terms by reducing perceived risk.”

From Factory to Foundation: Site Prep, Delivery, and Installation

A clear schedule that ties factory build steps to on-site work keeps the project on track and reduces surprises. Mapping the end-to-end plan helps owners, builders, and trades know roles, milestones, and expected handoffs.

Permits, hookups, and local standards

Start with permits, grading, and foundation specs that match local standards. Confirm utility hookups and inspection windows early so approvals line up with module delivery.

Tip: collect foundation details, utility maps, and permit timelines in one packet to speed reviews and avoid rework.

Coordinating timelines to reduce total build time

Run factory fabrication and site prep in parallel to cut overall time and lower carrying costs. Plan delivery logistics—staging, craning, and access routes—to protect the site and finishes during set day.

- Identify critical-path tasks and schedule inspections to avoid bottlenecks.

- Hold regular builder-owner checkpoints for quick decisions and change control.

- Complete commissioning and warranty documentation after installation to validate performance.

“Disciplined planning and clear communication minimize surprises and speed move-in.”

Sustainability Gains Over Time: Maintenance, Upgrades, and Resale Appeal

A steady plan of maintenance and staged upgrades keeps a home’s performance growing and its costs shrinking.

Energy and water upgrades compound savings. Add insulation, swap to efficient appliances, and install low-flow fixtures in phases. Each step lowers bills and raises comfort.

Energy and water upgrades that compound savings

Start with envelope improvements, then add controls and water-efficient fixtures. Over time these measures stack, creating real savings and resilience.

Market demand for green building and resale value

Demand for green homes is rising. Certified or documented performance often commands higher valuations and faster sales.

Maintenance preserves those gains. Simple routines—sealants, filter changes, and annual tune-ups—keep systems tight and lower long-term cost for homeowners.

Operational carbon and lasting impact. Better envelopes and added renewables cut emissions year after year. That reduces a home’s carbon footprint and operating expenses.

| Upgrade | Typical Cost | Primary Benefit |

|---|---|---|

| Extra insulation | Moderate | Lower heating/cooling bills |

| Heat pump retrofit | Higher | High efficiency, strong ROI |

| Smart thermostat & LEDs | Low | Immediate savings |

| Water-saving fixtures | Low–Moderate | Reduced water cost & resilience |

- Pick upgrades with proven ROI: smart thermostats, LED lighting, and heat pumps.

- Track performance with meters or apps to validate savings and guide future investments.

- Choose durable materials and smart details to cut repairs and downtime.

- Check incentives and tax credits to lower upfront costs.

“Buyer awareness of efficiency and indoor air quality is rising; documented performance can add real market value.”

Bottom line: sustainability is a plan, not a one-time project. Phased investments and steady care turn near-term work into long-term equity, lower operating cost, and measurable environmental impact.

Ready to Live Greener Today: Your Next Steps Toward a Portable, Sustainable Home

Ready to live greener today? Begin with a clear plan for sustainable living that turns goals into action. strong.

Modern prefab and modular options deliver proven benefits: faster delivery, lower waste, and strong energy performance in stylish homes.

List must-have features and request itemized bids that match your budget and options. Engage reputable builders early to confirm permits, schedule, and feasibility for your house.

Explore certification pathways for third-party proof and run a climate-aligned design review that prioritizes the envelope for the biggest efficiency gains.

Assemble financing documents—plans, specs, test reports, and timelines—to speed approvals. Plan for future ADU or expansion so the initial home supports flexible living and easy solar add-ons.

Take the next step: choose the solutions that fit, then contact a trusted builder to start your project now.

Leave a Reply