This buyer’s guide gives a clear, data-rich snapshot of what to expect when planning a modular or tiny house project in the United States.

Base numbers matter: many modular units run $50,000–$150,000, about $50–$100 per square foot. Tiny homes commonly land between $30,000 and $70,000 or $150–$450 per square foot for custom builds.

Beyond the structure, plan for delivery and setup ($10,000–$20,000), site work and foundation ($5,000–$20,000), and customization ($10,000–$50,000). Permits, utility upgrades, and access needs can add thousands more.

Read on to see side‑by‑side comparisons, typical upgrade paths, and simple rules for turning estimates into a realistic budget. This guide helps you match value with comfort and long‑term savings.

Key Takeaways

- Modular homes: $50k–$150k base; tiny houses: $30k–$70k typical.

- Delivery, site work, and permits often add $5k–$50k to the total cost.

- Per‑square‑foot rates vary widely by model and customization level.

- Location, access, and utilities shape final expenses more than expected.

- Use line‑item ranges to build a realistic budget and timeline for your project.

Today’s portable home price snapshot in the United States

Today’s market shows clear ranges for modular and tiny units, with location and finishes pushing totals higher.

Modular models typically list between $50,000 and $150,000 for basic units, or roughly $50–$100 per square foot for the base shell. Delivery and installation commonly add $10,000–$20,000.

Tiny houses average about $30,000–$70,000 to build. On a per‑square‑foot basis they often run higher (roughly $150–$450) because many fixed construction expenses spread over less size. Prefab tiny homes usually cost less than fully custom builds.

- Land varies: rural parcels can be $5,000–$18,000 per acre, while urban lots may cost far more.

- Lot rent for homes on wheels ranges from about $250 to $1,500 per month depending on amenities and location.

- Prefab models deliver faster timelines and steadier estimates; custom work raises the final total but tailors living space.

Portable home prices per square foot: what you’ll really pay

Listing dollars per square foot is common, yet it rarely tells the whole story for tiny and modular builds. Start with per‑square figures, then check what those numbers include.

Average per square foot vs. per square pricing explained

Per square quotes can exclude delivery, installation, and site work. Always ask whether finishes, appliances, and hookups are included. That keeps comparisons fair.

Tiny homes: $150-$450 per square foot and why it runs higher

Tiny houses often run $150–$450 per square foot. Fixed elements—kitchen, bathroom, HVAC—don’t shrink with size, so labor and premium finishes raise the per square rate. DIY builds may total $30,000–$60,000, while custom or prebuilt units commonly reach $50,000–$150,000+.

Modular basics: $50-$100 per square foot for the base structure

Modular base structures typically list at $50–$100 per square foot before delivery and site charges. Differences in materials, engineering, and high‑efficiency systems can shift that range.

- Per‑square‑foot quotes vary by inclusion—confirm line items.

- Compact design choices and custom cabinetry drive up per square and square foot figures.

- For true apples‑to‑apples, get itemized bids showing structure, finishes, and hookups.

What drives the total cost? Size, location, design, and beyond

Several big levers move the final budget: layout complexity, material choices, site logistics, and bespoke options. Each factor adds both to the structure and the finishing line items.

Size and layout

More bedrooms, extra bathrooms, and intricate floor plans raise labor and plumbing runs. That increases the structure and finish budgets.

Tip: Simple, efficient layouts save both time and money without sacrificing usable space.

Materials and finishes

Standard selections keep estimates steady. Premium choices — hardwood floors, stone counters, high‑end fixtures — push the house into higher brackets.

Expect luxury finishes and specialty materials to add thousands to the budget.

Location effects

Remote lots or dense urban sites require special transport, cranes, or staged assembly. That raises delivery and installation fees significantly.

Land markets also matter: in many regions the parcel cost can dominate the overall outlay.

Customization and features

Added items like upgraded insulation, heat pumps, and solar can add $10,000–$50,000 but reduce ongoing utilities. Smart storage and built‑ins raise craftsmanship time and cost.

- Bedrooms and baths increase plumbing and fixture expenses.

- Materials choices change final brackets more than square footage alone.

- Location dictates logistics and can add unforeseen fees.

- Energy and custom features raise upfront costs but often boost long‑term value.

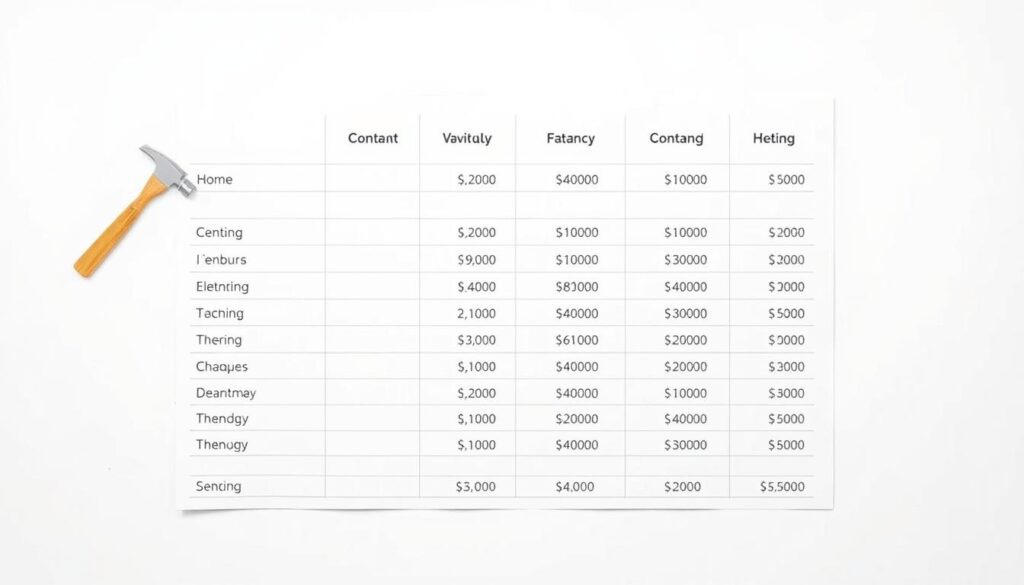

Portable home cost breakdown by line item

Breaking costs into clear line items removes guesswork and highlights where savings live.

Base structure and shell

Per square foot allowances set the base. Modular shells generally range from $50–$100 per foot for the structure. For tiny builds, framing and lumber can run $1,000–$14,000. Expect doors and windows at $1,000–$6,000, roofing $500–$2,000, siding $1,000–$3,000, and insulation $500–$3,000.

Foundation, site prep, and access

Foundation work usually lands between $3,000 and $8,000 for simple piers or slabs. Site prep, grading, and excavation add $5,000–$20,000. Land grading and excavation often include smaller line items ($500–$1,000 and $1,000–$2,500 respectively).

Labor, contractor fees, and timelines

Labor is often the largest share, typically 40%–60% of the total build. General contractor fees commonly range 10%–20% of construction or $50–$150 per hour. Plan timelines around subcontractor scheduling to avoid premium rush fees.

Interior finishes, appliances, and HVAC

Interior finishes vary by quality: flooring $2,000–$7,500 and fixtures $600–$4,300. Appliances for tiny units may run $400–$3,000, while full-size units cost more. HVAC options like mini‑splits are $2,500–$6,000 and water heaters $300–$2,600.

Delivery, installation, and setup

Delivery and set‑in costs can shift totals significantly. Modular installation often costs $10,000–$20,000. Tiny transport runs $1,000–$5,000. Crane work or difficult access can add $5,000 or more.

Practical tip: Add upgrades—better insulation or higher‑SEER systems—to upfront expenses for lower long‑term energy bills.

| Category | Typical Range | Notes |

|---|---|---|

| Structure (modular) | $50–$100 per square foot | Base shell before delivery and finishes |

| Framing & lumber (tiny) | $1,000–$14,000 | Depends on size and material quality |

| Foundation & site prep | $3,000–$20,000 | Includes slab/piers, grading, excavation |

| Labor & contractor | 40%–60% of build / $50–$150/hr | Largest single expense; GC fee 10%–20% |

| Finishes & appliances | $2,000–$7,500 (flooring); $400–$3,000 (appliances) | Quality choices drive final costs |

| Delivery & installation | $1,000–$20,000+ | Modular setup and crane access increase costs |

Land, permits, and zoning: budgeting for the property side

Securing suitable land and permissions often determines whether your project moves forward or stalls. Start by evaluating price, soil, slope, drainage, and access so the property is truly build‑ready.

Buying land: typical ranges and site suitability

National land averages sit near $5,000–$18,000 per acre, though desirable areas can reach $150,000 or more. Factor in clearing ($1,500–$6,700 per acre) and surveys ($200–$1,200).

Site tests for soils, perc, and access influence foundation and construction choices. Sloped or wet lots raise development costs and timeline.

Permits and inspections: local fees and code compliance

Permit fees vary widely. Tiny and modular permits commonly run $500–$5,000; tiny houses often fall between $900–$2,500.

Plan review and inspections require documents proving compliance. New utility runs add costs: water mains $32–$53 per linear foot and sewer $40–$180 per linear foot.

Zoning and ADU rules: where houses can go

Zoning dictates whether a house can be primary living space, an ADU, or only temporary. Many cities require permanent foundation for ADUs and separate utility meters.

Note: Houses on wheels are often treated like RVs and face stricter limits in some areas. Talk with planning and building departments early to avoid redesigns.

- Due diligence: surveys, perc tests, and utility feasibility protect your budget.

- Site factors: soil and access shape foundation and hookup needs.

- Regulations: zoning can limit long‑term placement and meter requirements.

| Item | Typical range | Notes |

|---|---|---|

| Survey | $200–$1,200 | Boundary and topography |

| Clearing | $1,500–$6,700/acre | Brush, trees, grading |

| Water main | $32–$53/ft | Connection to public supply |

| Sewer | $40–$180/ft | Depends on depth and terrain |

Transportation and installation costs most buyers overlook

Moving the structure from factory to lot can add unexpected logistics and fees. Plan these items early so they don’t delay site work or utility hookups.

Typical ranges: hauling for a tiny house often runs $1,000–$5,000 depending on distance. Modular delivery and installation commonly total $10,000–$20,000. Crane or special access may add $5,000+.

Hauling and crane services: distance and access challenges

Longer hauls mean more than fuel. They can require pilot vehicles, extra insurance, and permits that raise final expenses.

“Delivery quotes often exclude escorts, route changes, or road closure fees — always ask for a full hauling estimate.”

Foundation choices and set-in-place costs

Foundations vary by type. Tiny builds on piers typically cost $3,000–$8,000. Slabs usually run $6–$14 per foot and rise with larger homes.

- Confirm trailer capacity and braking if the house will move often.

- Tight sites may need crane time, staging, or temporary road mats.

- Weather windows and crew availability affect labor and schedule.

| Service | Typical range | Notes |

|---|---|---|

| Tiny house hauling | $1,000–$5,000 | Distance and permits affect total |

| Modular delivery & installation | $10,000–$20,000 | Includes set‑in; access can add fees |

| Crane / special access | $5,000+ | Needed for tight or obstructed lots |

| Trailer (THOW) | $4,500–$11,000 | Required for houses on wheels |

| Foundation (piers) | $3,000–$8,000 | Leveling, anchoring, final inspection |

Utility hookups and off‑grid options: water, sewer, power

Utility connections shape upfront installation and monthly bills for any small home or house project. Good planning avoids surprise fees and keeps living space comfortable.

Grid connections and meter fees

Grid hookups require permits and may include meter charges of $2,000–$3,000+ in some cities. Trenching distance, dedicated service, and trench restoration add to installation costs.

Septic vs. sewer, water mains, and rainwater systems

Sewer taps run about $40–$180 per linear foot; new water mains cost roughly $32–$53 per foot. Where sewer isn’t available, septic systems typically range $3,500–$8,500 and need perc tests.

Off‑grid options — rainwater collection and composting toilets — reduce utility bills but need upfront sizing and treatment planning.

Electrical service, solar add‑ons, and ongoing utilities

Electrical hookup fees vary: urban connections often start near $250–$1,500, while rural runs can hit $2,000–$5,000+. Many small homes use 30‑ or 50‑amp services and 120V appliances.

Solar systems for tiny houses typically cost about $3,500–$8,800 after tax credits. Expect monthly utilities for tiny homes to average $100–$250.

- Plan early: confirm meter, trench, and permit requirements with local utilities.

- Sizing matters: right‑sized mini‑splits and insulation cut long‑term bills.

- Compare options: grid vs. off‑grid affects both budget and living independence.

| Service | Typical range | Notes |

|---|---|---|

| Water main | $32–$53/ft | Connection and trenching |

| Sewer | $40–$180/ft | Distance and depth drive costs |

| Septic system | $3,500–$8,500 | Requires soil and perc tests |

| Solar (tiny) | $3,500–$8,800 | After federal tax credit |

Base types and their price impacts

Different build platforms—trailers, slabs, containers, buses—carry distinct expenses and tradeoffs. Your choice affects permits, financing, parking, and long‑term living flexibility.

On wheels: trailer types, certification, and lot rental

Houses on wheels (THOW) commonly range from $30,000–$70,000+ including the trailer. Trailers alone run about $4,500–$11,000. RVIA certification can simplify classification as an RV, and many renters pay $250–$1,500 per month for lot space.

Permanent foundation: slabs, piers, and crawlspaces

Permanent foundations add stability and often ease zoning and lending. Expect full tiny‑house foundations to start near $33,000–$78,000+ (land excluded). Slab work is typically $6–$14 per square foot.

Shipping container builds

Single‑container homes can be economical at roughly $20,000–$50,000. Multi‑container designs become structural projects and usually cost $100,000–$250,000+ due to steel cutting, reinforcement, and insulation needs.

Park models and bus conversions

Park models often reach 400–500 square feet and compete with high‑end tiny houses on finishes and systems. Bus conversions bundle chassis and structure; total budgets commonly sit around $30,000–$50,000, while donor buses run $4,000–$10,000+.

| Type | Typical range | Key implications |

|---|---|---|

| On wheels (THOW) | $30,000–$70,000+ | Mobility, trailer cost, RVIA, lot rent |

| Permanent foundation | $33,000–$78,000+ | Zoning, financing, higher permits |

| Slab (per square foot) | $6–$14/ft | Simple, durable; cost scales with size |

| Shipping container (single) | $20,000–$50,000 | Steel work, insulation, efficient reuse |

| Multi‑container | $100,000–$250,000+ | Structural reinforcements, higher materials |

| Bus conversion | $30,000–$50,000 | Chassis + interior systems integration |

How Much Does a Portable Home Cost? Price Breakdown by home type

Whether you pick a towable tiny or a multi‑unit modular, each option brings a different budget profile and timeline.

Tiny houses: DIY, prefab, and custom ranges

DIY tiny builds often land between $30,000 and $60,000 thanks to sweat equity and lower materials spending.

Prefab tiny fully finished models commonly run $25,000–$80,000 for predictable delivery and set scopes.

Custom tiny projects can exceed $50,000 and reach $140,000+ when high‑end finishes, appliances, and tailored design raise per square foot costs.

Modular homes: basic to luxury tiers

Basic modular shells typically start $50,000–$150,000. Double‑wide units sit near $80,000–$150,000. Expandable systems range $70,000–$200,000+, and luxury series climb $150,000–$300,000 with premium interior features and systems.

Steel frame, multi‑family, and foldable options

Steel frame modular builds aim for durability and higher weather resistance; budget roughly $120,000–$250,000.

Multi‑family modulars often begin around $150,000–$300,000+ per unit and suit investment strategies by spreading land and installation costs.

Foldable and rapidly deployable units provide quick setup at roughly $50,000–$100,000, ideal for ADUs or emergency deployments.

- Clarify inclusions: roof type, appliances, interior finishes, and installation before comparing quotes.

- Note labor and materials vary by region and design complexity.

DIY vs. prefab vs. custom: which path fits your budget and timeline

Choosing DIY, prefab, or custom routes changes budget, calendar, and required skills for any small house project.

DIY: lowest cash outlay, highest time and skill requirements

Typical range: tiny DIY builds often total $30,000–$60,000 and demand roughly 500–1,000 hours of work.

Pros: sweat equity reduces cash spent and gives full control over design and finishes.

Cons: steep learning curve, heavy labor, and longer schedules; if hiring trades, labor and contractor fees still apply.

Prefab kits and fully finished models: speed and predictability

Kits run $4,000–$30,000 unassembled; shells $15,000–$40,000; finished models typically sit between $25,000–$80,000.

Prefab compresses construction time and lowers on‑site labor. It is a good option if you value schedule certainty and fewer surprises.

Custom builds: tailored design at a premium per square foot

Custom tiny projects commonly start near $50,000 and can exceed $140,000 depending on materials and finishes.

Expect contractor fees of 10%–20% or $50–$150 per hour, and labor often makes up 40%–60% of total. Custom work delivers tailored space but increases coordination and risk of scope creep.

| Path | Typical range | Main tradeoffs |

|---|---|---|

| DIY | $30k–$60k; 500–1,000 hrs | Low cash, high time, high skill needed |

| Prefab (kit/shell/finished) | $4k–$80k | Faster timeline, predictable scope, less on‑site labor |

| Custom | $50k–$140k+ | Full design control, higher contractor and labor spend |

Bottom line: match your available time, tolerance for on‑site work, and desired level of design control to the option that fits your budget and move‑in timeline.

Regional price differences across the United States

Region and local rules can swing final budgets by tens of thousands, even when per‑square estimates look similar. Use state averages and local fees to translate national ranges into realistic totals for your plan.

High‑cost areas vs. affordable states

Some states show markedly lower averages for tiny projects. For example, North Dakota (~$28,000), Arkansas (~$31,700), Kansas (~$33,500), and Mississippi (~$34,500) sit near the affordable end.

By contrast, Hawaii (~$149,100), Montana (~$78,400), and California (~$75,600) push budgets up due to higher labor, shipping, and permitting fees.

Urban, suburban, and rural build realities

Urban infill raises costs for staging, restricted delivery windows, and higher permit fees. That makes city builds pricier even when per‑square numbers seem moderate.

Suburban lots often balance access and costs, while rural sites can save on labor but add expenses for longer utility runs and road improvements.

- Key drivers: labor rates, permitting, supplier access, and demand vary by location.

- Land matters: national averages sit near $5,000–$18,000 per acre but vary widely by region.

- Consider taxes, insurance rules, and local acceptance of small house types before choosing property.

Portable home value compared to traditional and manufactured homes

Upfront savings often look attractive,> but long‑term returns depend on placement, classification, and market acceptance. Modular units typically list near $50,000–$150,000 while traditional home builds commonly start above $200,000. Tiny houses often fall between $30,000 and $70,000 and usually finish faster.

Upfront budgets, construction time, and labor

Tiny projects often complete in 2–4 months; small houses commonly need 7–8 months. That shorter timeline cuts labor inputs and staging fees.

Quick note: modular shells save time, but confirm which line items—materials, appliances, interior finishes—are included before signing.

Energy efficiency, maintenance, and insurance

Right‑sized envelopes, higher insulation, and efficient HVAC lower utilities and long‑term costs. Smaller footprints reduce annual maintenance for roofs and exterior materials.

Insurance runs vary: tiny units often cost $35–$125 per month and may require RV or manufactured policies. Units on a foundation face property taxes instead of registration fees.

Resale value, appreciation, and financing considerations

Traditional homes tend to appreciate; tiny houses can depreciate, especially if towable. Resale depends on condition, local market acceptance, and location.

- Financing favors foundation‑set dwellings; lenders often treat them like traditional property.

- For best long‑term value, match the structure to your target property and local rules.

Ready to budget your portable home? Smart next steps for confident buyers

Start with a realistic budget envelope that covers the unit, land, installation, and likely extras. Include site prep, permits, and a contingency so bids stay comparable.

Practical next steps: shortlist builders whose models match your must-have features and location limits. Verify zoning and permit pathways before you sign any contract. Delivery and set-in for modular units often add $10,000–$20,000; tiny transport commonly runs $1,000–$5,000; expect permits near $900–$2,500+

Request line-item bids that separate structure, finishes, appliances, and installation. Sequence lead times for fabrication, hauling, and inspections. Plan maintenance and warranty support to protect long-term value of your home and keep the project on time.

Leave a Reply